Types of Stone Slabs and Their Applications in Construction

2025-12-08

What Is the Difference Between First-Grade, Second-Grade, and Export Stone?

2025-12-20Key Quality Factors in Purchasing Building Stone | Mr Silver

Selecting high-quality building stone is one of the most critical decisions in any construction or architectural project. Building stone not only defines the visual identity of a structure but also plays a fundamental role in durability, safety, long-term maintenance costs, and overall property value. Poor-quality stone can lead to cracking, discoloration, water penetration, and costly repairs over time.

In this comprehensive guide by Mr Silver, we examine in detail the most important quality factors you must consider before purchasing building stone, helping you make a smart, long-lasting, and cost-effective choice.

1. Type of Building Stone and Intended Application

Each type of building stone has unique physical and chemical characteristics, and selecting the wrong stone for a specific application can significantly reduce its lifespan.

- Travertine: Excellent choice for building facades due to its strong adhesion to mortar and resistance to weather conditions.

- Granite: Extremely hard and durable, ideal for high-traffic flooring, staircases, and commercial spaces.

- Marble: Known for its elegance and luxurious appearance, best suited for interior walls and low-traffic floors.

- Crystal (Porcelain) Stone: Low water absorption and high resistance to moisture, making it suitable for wet areas.

Choosing the correct stone type ensures optimal performance and prevents premature damage.

2. Compressive Strength and Structural Durability

Compressive strength is a key indicator of stone quality. High-quality stone must withstand heavy loads, daily usage, and environmental stress without cracking or breaking.

This factor is especially important for floors, staircases, and exterior cladding exposed to wind pressure and temperature fluctuations.

3. Water Absorption and Porosity

Low water absorption is essential for long-term durability, particularly in outdoor applications.

- High water absorption may cause staining, freeze-thaw damage, and surface erosion.

- Low water absorption improves resistance to moisture, frost, and weathering.

Professionally processed stones usually perform better in this aspect.

4. Color Consistency and Surface Texture

Premium building stone features uniform color, stable texture, and a natural pattern without visible defects.

Buyers should inspect:

- Color consistency across slabs

- Absence of cracks or weak veins

- No signs of rust stains or salt deposits

Uniform appearance is especially important for luxury architectural projects.

5. Processing, Cutting, and Finishing Quality

Even the highest-quality raw stone can lose value if processed poorly.

High-quality processing includes:

- Precise cutting with standard dimensions

- Uniform thickness

- Smooth, even polishing

- Clean edges without chipping

At Mr Silver, modern processing technology ensures consistent and export-grade quality.

6. Standard Thickness and Dimensions

Stone thickness must match its application. Proper thickness ensures structural safety, easier installation, and longer service life.

7. Resistance to Environmental Conditions

Quality building stone must resist sunlight, temperature changes, frost, humidity, and air pollution, especially in exterior applications.

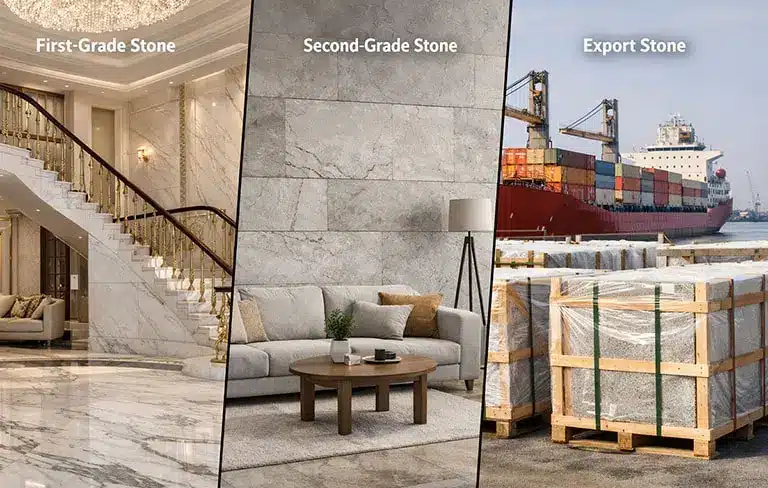

8. Stone Grading and Sorting

Stone grading plays a major role in quality and pricing:

- Grade A: Uniform color, minimal defects, suitable for luxury projects

- Grade B: Economical choice with acceptable quality

- Export Grade: Highest standards in processing and appearance

9. Price Versus Quality Value

The cheapest option is rarely the best. High-quality stone offers better durability, lower maintenance costs, and higher property value over time.

10. Supplier Reliability and Expertise

Purchasing from a reputable supplier ensures consistent quality, expert consultation, and reliable after-sales support.

Mr Silver provides professionally sorted stone, technical guidance, and solutions suitable for both domestic and international projects.